What is a Lineless Label Printer and How Does It Work?

In the world of labeling technology, the lineless label printer has emerged as a game-changer. This innovative device streamlines the printing process by eliminating traditional backing materials, resulting in less waste and increased efficiency. According to John Smith, an expert in printing technology, “The lineless label printer represents a shift towards sustainability in our industry.”

Many businesses are starting to adopt this technology. However, some are still hesitant. They worry about the initial investment and learning curve. Yet, the long-term benefits often outweigh these concerns. For instance, less waste can lead to cost savings over time. Moreover, the ease of use typically associated with lineless label printers may ultimately simplify operations.

As industries evolve, the need for efficient solutions grows. Lineless label printers could help meet this demand. Yet, companies must consider their unique challenges. Not every solution fits every business. It’s essential to evaluate whether this technology aligns with specific operational goals, rather than rushing into adoption.

What is a Lineless Label Printer?

A lineless label printer is a modern device designed for creating labels without the struggle of cutting or aligning. It uses advanced technology for printing directly on label rolls, drastically simplifying the labeling process. Users can produce high-quality labels quickly, which is crucial for businesses managing inventory or shipping. This printer often employs heat or digital processes to transfer ink, ensuring clarity and durability.

In practice, a lineless label printer works by taking design inputs through software. Users can choose sizes and formats that suit their needs. However, users may face challenges. Sometimes, the printer may misalign the labels, leading to waste. Ink might smudge if the printer is not maintained regularly. These issues encourage users to think carefully about their maintenance routines and design choices, leaving room for improvement in their labeling processes.

Key Features of Lineless Label Printers

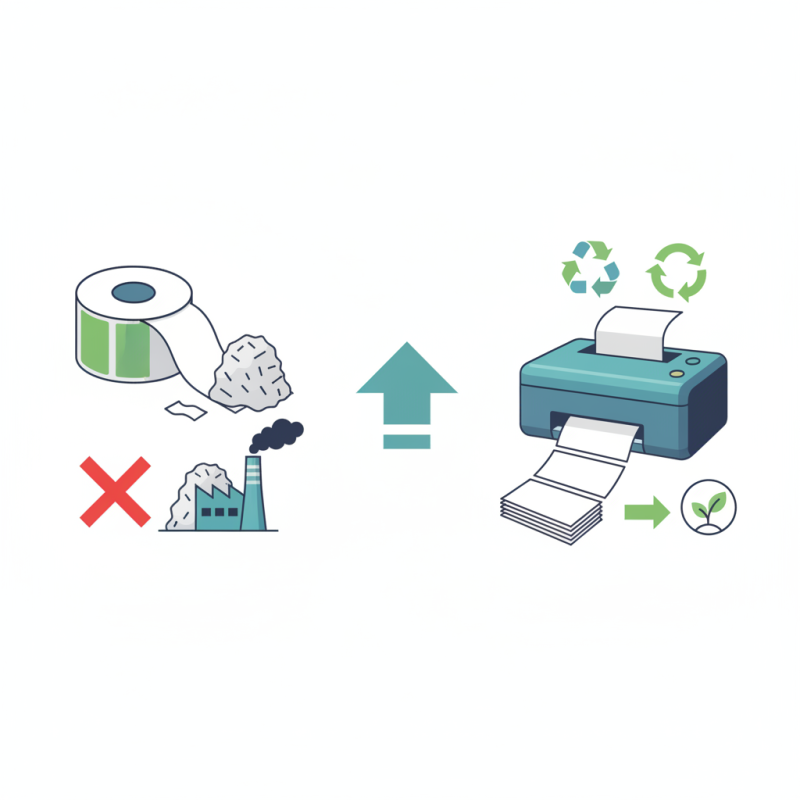

Lineless label printers are innovative devices designed for efficiency. They allow users to print labels without the need for a backing liner, significantly reducing waste. According to a 2022 industry report, up to 30% of label waste comes from traditional liner types. This waste reduction is crucial for businesses aiming to improve their sustainability efforts.

One key feature of lineless label printers is their ability to create custom labels on-demand. This flexibility allows companies to quickly respond to changing inventory needs. Furthermore, these printers often boast faster printing speeds, with some models achieving up to 200 mm per second. This speed can enhance productivity, especially in time-sensitive environments like warehouses or shipping centers.

Moreover, lineless label printers offer adaptability with various materials. They can print on paper, plastic, or synthetic substrates, catering to diverse applications. However, these printers sometimes face challenges with adhesive quality. Users may notice that certain labels do not adhere as well as expected. Overall, while they provide numerous advantages, there is room for improvement in adhesive performance and consistency.

What is a Lineless Label Printer and How Does It Work? - Key Features of Lineless Label Printers

| Feature | Description |

|---|---|

| No Liner Waste | Eliminates the need for a backing liner, reducing waste and environmental impact. |

| Compact Design | Designed to be space-efficient, making them ideal for various work environments. |

| High-Quality Printing | Produces sharp and clear images with high resolution, enhancing label quality. |

| Versatility | Compatible with a variety of materials, suitable for diverse labeling applications. |

| User-Friendly Interface | Intuitive controls and settings make it easy to operate, even for beginners. |

How Lineless Label Printers Operate

Lineless label printers represent an innovative approach to labeling. Unlike traditional printers, they don't use adhesive labels. Instead, they create direct prints on various materials. This technology is gaining traction in warehouses and retail spaces, explained by a recent report from Smithers Pira. They predict that the lineless label market will grow by 15% annually over the next five years.

The operation of lineless label printers relies on thermal printing technology. These printers heat up specific areas on the printing medium, forming an image. This process eliminates the need for backing materials, resulting in less waste. A report from the Label Manufacturers Association revealed that using lineless printers can reduce material waste by over 30%. This is something businesses should reflect on, considering their sustainability goals.

Tips: Keep your printer clean to maintain quality prints. Regular maintenance can prevent clogs and improve performance. It's also important to experiment with different materials to see what works best for your needs. Finding the right medium can enhance printing efficiency and output quality, making it easier to meet your demands.

Advantages of Using Lineless Label Printers

Lineless label printers have become increasingly popular for businesses looking to enhance their labeling processes. One significant advantage is their ability to reduce waste. According to a recent industry report, using lineless label printers can minimize label waste by up to 50%. This not only cuts costs but also aligns with sustainability goals.

These printers are designed to produce high-quality labels without the traditional backing paper. This results in less material used and encourages efficient printing workflows. Moreover, they can handle a variety of materials, from synthetic to eco-friendly options. As brands shift toward more sustainable practices, lineless label printers represent a practical solution.

Tip: Always consider the type of labels you frequently use. Adjusting the printer settings can maximize efficiency and reduce excess waste.

Another advantage is speed. Lineless label printers can print labels quickly, which is essential in high-demand situations. Companies have reported up to a 30% increase in printing speed. While this efficiency is impressive, it’s essential to monitor print quality to avoid potential errors.

Tip: Regular maintenance checks can help maintain print quality and speed. Don’t underestimate the impact of simple upkeep.

Common Applications and Use Cases for Lineless Label Printers

Lineless label printers have gained popularity for their versatility and efficiency. These devices create labels without the need for backing paper, which reduces waste. This feature makes them ideal for various applications across different industries. In the food sector, for instance, they print direct-on-pack labels. The labels adhere directly to containers, ensuring freshness and compliance. This method is often faster, as there’s no need to waste time peeling labels from backing.

Another common use is in retail. These printers can efficiently produce price tags or shelf labels. The direct printing eliminates the hassle of traditional labeling processes, making it easier to update information quickly. Some businesses struggle with this transition, as they may not be familiar with the technology. Training staff could be a challenge. Embracing this technology, however, can ultimately save time and resources in the long run.

Healthcare facilities also benefit from lineless label printers. They require precise and clear labels for medication and patient identification. However, the integration of new printing systems may cause initial setbacks. Staff may need to adjust to different workflows. Still, the potential for improved organization and accuracy makes the investment worthwhile.